Microfiber cloths are a modern cleaning essential, known for their exceptional performance and versatility. Whether you’re tackling household chores, detailing your car, or polishing jewelry, microfiber cloths deliver impressive results. This comprehensive guide explains everything about microfiber cloths, from their composition and types to their uses and care.

What is Microfiber Cloth?

A microfiber cloth is a cleaning tool made from extremely fine synthetic fibers, typically polyester and nylon. These fibers are highly effective at trapping dust, dirt, and moisture, making microfiber cloths ideal for cleaning delicate surfaces like electronics, eyeglasses, and furniture without causing scratches. They also reduce the need for chemical cleaners, making them an eco-friendly option.

What is Microfiber Cloth Made Of?

Polyester

Polyester provides microfiber cloths with strength, durability, and resistance to shrinking and stretching. It forms the backbone of the cloth’s structure.

Polyamide

Polyamide, also known as nylon, contributes softness, elasticity, and excellent moisture-wicking properties. This makes microfiber cloths highly absorbent and gentle on surfaces.

Fiber Blend Ratios

Most microfiber cloths are typically made from an 80% polyester and 20% polyamide blend, which strikes a balance between durability and absorbency. However, depending on the specific cleaning task, different ratios may be used to enhance performance:

- 80% Polyester, 20% Polyamide: This blend is the most common, offering a solid combination of strength, durability, and effective cleaning power.

- 100% Polyester: Used for lightweight and non-abrasive applications, offering excellent durability and lint-free performance. Ideal for polishing and delicate surfaces.

- 90% Polyester, 10% Polyamide: A versatile blend that combines the benefits of polyester’s durability and polyamide’s absorbency, making it ideal for general cleaning tasks while still maintaining good performance in moisture retention.

Each fiber blend is selected to match specific cleaning tasks, ensuring optimal performance and durability.

What is GSM in Microfiber Cloth?

GSM (grams per square meter) measures the density and quality of a microfiber cloth. Higher GSM values indicate thicker, more absorbent cloths suitable for heavy-duty cleaning, while lower GSM cloths are lighter and ideal for polishing.

- For glasses, jewelry, watch and electronic products cleaning, usually from 170gsm-300gsm.

- For Kitchen cleaning, usually 300gsm, 400gsm

- For Car cleaning, usually 300gsm, 400gsm, And combine 2 kinds of microfiber as 500gsm, 800gsm, and 1200gsm

Types of Microfiber Cloth

Microfiber cloths come in a variety of types, each designed for specific applications to maximize their cleaning potential. The following are the most common types:

Terry Microfiber Cloths:

These cloths feature a looped texture that enhances absorbency, making them ideal for general cleaning, dusting, and wiping. They come in two types:

-

- Warp Knitting Terry Towel: This type of towel is made using warp knitting, creating a more durable and resilient structure. It’s commonly used in general cleaning tasks where durability and absorbency are essential.

-

- Weft Knitting Terry Towel: Made with weft knitting, this version is softer and more flexible. It’s typically used for delicate cleaning tasks where gentleness is important, such as for surfaces that require extra care, like glass or wood.

Ultra-Soft Microfiber Cloths:

These cloths are designed specifically for cleaning delicate surfaces such as lenses, eyeglasses, jewelry, watches, and electronic products. They are extremely soft, ensuring no scratches or abrasions on these sensitive items while still effectively removing dust, fingerprints, and smudges.

Waffle Weave Cloths:

Featuring a textured pattern resembling a waffle, these cloths are designed for high absorbency and drying. They’re perfect for tasks such as drying dishes, cleaning windows, or wiping down countertops.

Special Microfibers:

These cloths are made with unique textures and finishes, such as stripes, glossy patterns, or composite materials. These special microfibers are often used for specialized tasks where specific textures are needed to enhance performance or aesthetics.

What is Microfiber Cloth Used For?

Household Cleaning

Microfiber cloths make cleaning windows, countertops, and floors easier, leaving surfaces streak-free and spotless.

Car Cleaning

Car enthusiasts use microfiber cloths for washing, waxing, and detailing, ensuring a scratch-free finish on paint and interiors.

Personal Care

Soft microfiber towels are excellent for drying hair, removing makeup, and exfoliating gently.

Optical Equipment

Delicate surfaces like eyeglasses, camera lenses, and binoculars benefit from microfiber’s lint-free and scratch-free properties.

Electronics Cleaning

- Smartphones and Tablets: Removes smudges and fingerprints without scratching.

- Computer Monitors: Dusts screens and keyboards effectively.

Polishing

- Metal Polishing: Shines chrome, stainless steel, and silver.

- Jewelry Polishing: Safely cleans intricate and delicate pieces.

Microfiber Cloth Benefits

Absorbency

Microfiber can hold up to seven times its weight in water, making it ideal for spills and heavy-duty cleaning.

Durability

Microfiber cloths withstand frequent washing and retain their effectiveness over time.

Lint-Free

They leave no residue, ensuring streak-free results on mirrors, glass, and polished surfaces.

Electrostatic Properties

Microfiber generates an electrostatic charge that attracts and holds dust and allergens effectively.

Microfiber Manufacturing Process

Extrusion Process

Microfiber fibers are created through an extrusion process that produces ultra-fine synthetic threads.

Splitting Technique

Fibers are split into even finer strands, increasing the surface area for superior cleaning performance.

Dye Colors

Cloths are dyed to create a variety of colors, often used for task-specific coding.

Surface Texturing

Microfiber surfaces are textured during manufacturing to suit different cleaning applications.

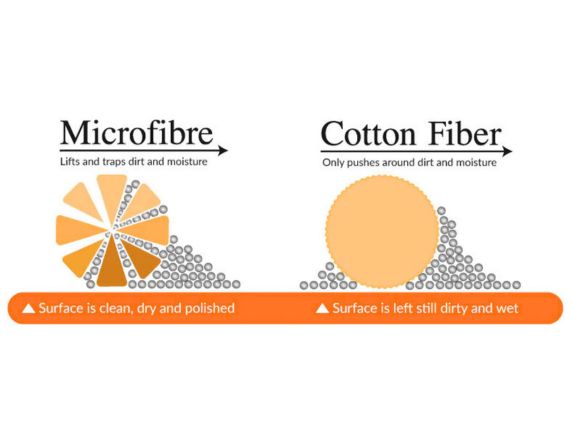

Microfiber vs. Cotton

| Feature | Microfiber | Cotton |

|---|---|---|

| Cleaning Efficiency | Traps dirt and bacteria effectively | Absorbs well but pushes dirt around |

| Durability | Retains shape and cleaning power | Wears out faster |

| Absorbency | Holds significantly more water | Absorbs less and dries slower |

| Surface Safety | Non-abrasive, safe for delicate surfaces | May leave lint or scratches |

| Cost Comparison | Cheaper but less durable | Higher initial cost, better long-term value |

How to Wash Microfiber Cloths?

- Wash Separately: Avoid mixing with cotton to prevent lint transfer.

- Use Mild Detergent: No fabric softeners or bleach, as they can damage fibers.

- Air Dry or Low Heat: High heat can melt the fibers.

- Shake Out Debris: Remove trapped particles before washing.

Market Trends Sustainability

Eco-Friendly Microfiber

Manufacturers are reducing chemical use and exploring biodegradable options.

Recycled Microfiber

Recycled materials are being used to produce microfiber cloths, supporting circular economy practices.

Branding and Customized Printing

Customized microfiber cloths offer businesses a unique way to enhance their branding. By adding logos, slogans, or designs through various printing techniques, companies can turn microfiber cloths into effective promotional tools.

Custom Printing Techniques

- Screen Printing: Cost-effective and ideal for bold logos or text.

- Embossing: Creates a raised design for a premium look.

- Digital Printing: Allows for full-color, intricate designs.

- Heat Transfer Printing: Durable and vibrant, suitable for multi-color designs.

Benefits of Branding Microfiber Cloths

- Increased Brand Visibility: Custom designs ensure that your logo is always visible during use.

- Practical Marketing Tool: High usability ensures frequent interaction with the branded product.

- Corporate Gifting: Adds a personal touch to gifts for clients or employees.

Popular Applications

- Promotional Giveaways: At trade shows, events, or conferences.

- Retail Packaging: Microfiber cloths included in branded packaging for electronics or eyewear.

- Corporate Gifts: Personalized microfiber towels or cleaning cloths for employees or partners.

Microfiber cloths are an innovative solution for effective, eco-friendly, and versatile cleaning. Whether you need a high-performance tool for household chores, personal care, or industrial use, understanding microfiber’s benefits and applications ensures you make the most of this exceptional material.