Table of Contents

ToggleBrief Description

When customers inquire about the origin of microfiber cloths, they often hope to hear that they are made domestically. However, the reality is that the vast majority of microfiber cloths are manufactured in China. China has established itself as the leading producer of microfiber products, with numerous factories specializing in their production. This concentration of production in China is due to the country’s advanced manufacturing capabilities, cost-effective labor, and well-developed supply chains, making it the primary source for microfiber cloths worldwide.

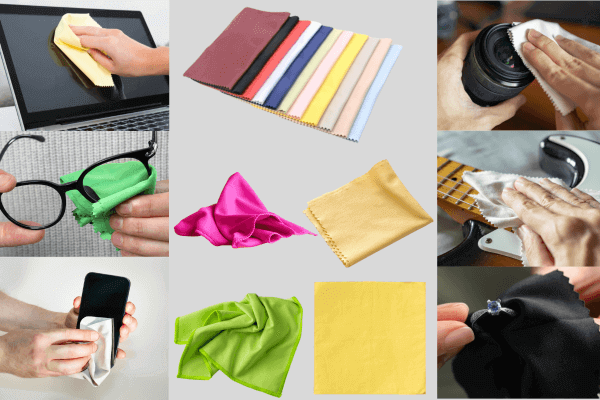

China’s microfiber cloth manufacturers offer comprehensive, one-stop services encompassing spinning, weaving, dyeing, customization, sewing, and packaging. This integrated approach enables clients to reduce procurement costs by 10% to 20%. These manufacturers are proficient in producing both warp and weft-knitted towels of various weights (gsm) and designs, catering to diverse needs such as household cleaning, automotive care, pet grooming, and the microfiber Cleaning cloth for eyeglasses, jewelry, watches, instruments, and musical equipment.

How to manufacture microfiber cloth?

- Fabric Production: The process begins with the selection of high-quality polyester and polyamide fibers. These materials are chosen for their strength, flexibility, and absorbency, which are crucial for the performance of the final product.

Fabric Warping

Fabric production - Microfiber Weaving: The selected fibers are woven into a fabric using advanced weaving techniques. The weaving pattern influences the cloth’s texture, absorbency, and durability.

Warp knitting

Weft knitting - Dyeing: The woven fabric undergoes a dyeing process to achieve the desired color. This step ensures that the cloth meets aesthetic requirements and can withstand multiple washes without fading.

Dying the color

Material finished - Microfiber Cutting: Automated cutting machines precisely cut the dyed fabric into specific sizes and shapes, such as 16×16 microfiber towels or custom screen cleaning cloths. Manual cutting techniques may also be employed for specialized designs.

Microfiber cloth Manual cutting

Microfiber towel Manual cutting

Automatic cutting

Automatic Sew and cut - Custom Printing: To enhance branding and functionality, custom printing methods like silk printing, embroidery, embossing, and full-color printing are applied. These techniques allow for personalized designs and logos on the microfiber cloths.

Silk printing

Deboss production

Embroidery

sublimation printing - Microfiber Sewing: Industrial sewing machines are used to stitch the cut pieces together, ensuring durability and a professional finish. Specialized stitching techniques may be employed for specific applications, such as creating lint-free edges for glass cleaning cloths.

Microfiber cloth sewing - Quality Control: Each batch undergoes rigorous quality control measures to ensure the microfiber cloths meet industry standards. Tests for absorbency, durability, and colorfastness are conducted to guarantee product excellence.

- Packing and Shipping

-

Supply Chain Centers of Microfiber Cloth Suppliers

Changshu, JiangsuChangshu, located in Jiangsu Province, is a prominent center for microfiber cloth production. The city boasts a well-established textile industry, providing access to raw materials and skilled labor. Changshu’s strategic location near major ports facilitates efficient distribution to domestic and international markets.

Several manufacturers in Changshu specialize in various microfiber products, including cleaning cloths, towels used for household cleaning, car cleaning, window and flooring cleaning, and mop pads.

Gaoyang, Hebei

Gaoyang County in Hebei Province is renowned for its textile industry, including microfiber cloth production. The region benefits from a rich history in textile manufacturing, providing a skilled workforce and access to raw materials. Gaoyang’s strategic location near major transportation routes facilitates efficient distribution to domestic and international markets.

Manufacturers in Gaoyang specialize in various microfiber products, including Various Cleaning towels like Coral fleece, Microfiber and mop pads.

- Wuxi, Jiangsu Province is a significant hub for microfiber cloth manufacturing. The city boasts a robust textile industry, providing access to raw materials and skilled labor. Wuxi’s strategic location near major ports facilitates efficient distribution to domestic and international markets.Several manufacturers in Wuxi specialize in various microfiber products, including microfiber cleaning cloths for screen cleaning, eyeglasses cleaning cloth, jewerly cleaning cloth, silver polish coth etc.

- Guangdong, China: Guangdong’s manufacturing sector is renowned for its advanced technology and high production capacity. The province hosts several microfiber cloth manufacturers that cater to both local and global demands. Guangdong’s robust infrastructure and export-oriented economy make it a pivotal player in the microfiber cloth supply chain.

Product Offering of Microfiber Cloths

- Microfiber Cleaning Cloths: Ideal for general cleaning tasks, these cloths effectively remove dust, dirt, and moisture from surfaces without the need for chemical cleaners.Phone /Laptop/computer Screen cleaning, eyeglass lens cleaning cloth, jewerly cleaning and polish, instrument cleaning etc

It’s smooth, silk-like, thin and soft microfiber cloth (Usually in 100% polyester, or 80% polyester&20% polyester)

Gsm from 170gsm, 190gsm,200gsm, 230gsm, 240gsm

Thin and soft microfiber cloth usage - Microfiber cleaning Towels: Also known as microfiber cloth, the size is under 50x50cm still called microfiber cloth. Designed for kitchen use, automotive detailing, gym use, and other commercial applications., these towels are highly absorbent and quick-drying, making them perfect for cleaning. Available in various sizes and weights, pattern, colors.There are different kinds of towel in different GSM (From 300gsm, 400gsm to 1200gsm), pattern (Striped, waffle, woven) for cleaning towel

Various microfiber: Coral Fleece, Waffle, microfiber

Microfiber cloth usage - Glass/Window Cleaning Cloths: Engineered to leave glass surfaces streak-free, these cloths are essential for cleaning windows, mirrors, and glassware.

- Custom Microfiber Cloths And Microfiber towel: We offer OEM/ODM services to create microfiber cloths with custom sizes, colors, and branding to meet specific client requirements.

Custom way for thin microfiber cloth: You Can dye the color as your request for 300-500 meters

Custom any size, custom edge like sewing, straight, zigzag

Imprint way: Full color printing, deboss logo, silk printing, gold/silver foil

Custom microfiber cloth for promotion, eyeglasses, screen - Custom way for thick microfiber cloth or called microfiber towel: You Can dye the color as your request for 500 meters

Custom any size, and custom edge: Ultrasonic, edgeless towel, sewing towel

custom pattern: Weft knitting, Wrap Knitting with special pattern like striped pattern, shinny effect etc.

Imprint way: Full color printing, deboss/emboss logo, embroidery, silk printing, sew the label

Custom microfiber towel for car, golf, rally towel etc - Custom way for thick microfiber cloth or called microfiber towel: You Can dye the color as your request for 500 meters

-

Certifications for Microfiber Cloth Suppliers

When selecting a microfiber cloth supplier, it’s essential to consider various certifications that ensure product quality, environmental responsibility, and ethical manufacturing practices. Key certifications to look for include:

1. Social Responsibility and Ethical Standards

- BSCI (Business Social Compliance Initiative): This certification assesses a company’s adherence to social responsibility standards, focusing on labor rights, fair wages, and safe working conditions. It’s particularly relevant for manufacturing and trading enterprises.

- Sedex (Supplier Ethical Data Exchange): Sedex is a global membership organization dedicated to driving improvements in ethical and responsible business practices across global supply chains. It covers areas such as labor standards, health and safety, the environment, and business ethics.

2. Environmental Management

- ISO 14001: This international standard specifies requirements for an effective environmental management system (EMS). It provides a framework for organizations to protect the environment, respond to changing environmental conditions, and meet socio-economic needs.

- GRS (Global Recycled Standard): The GRS is an international, voluntary, full product standard that sets requirements for third-party certification of recycled content, chain of custody, social and environmental practices, and chemical restrictions.

3. Product Safety and Quality

- OEKO-TEX® Standard 100: This certification ensures that textile products are tested for harmful substances and are safe for human health. It is globally standardized and updated annually to align with new scientific findings and regulatory requirements.

- SGS Certification: SGS is a leading inspection, verification, testing, and certification company. SGS certifications confirm that products have been tested and comply with national and international regulations and standards.

- REACH Compliance: REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is a European Union regulation aimed at ensuring a high level of protection for human health and the environment from chemical substances. Suppliers compliant with REACH demonstrate that their products meet stringent safety standards regarding chemical use.

By choosing suppliers with these certifications, you can be confident in the quality, safety, and ethical production of the microfiber products you procure.

-

-

List Of Microfiber cloth manufacturers

1. Changshu Jiarun Weaving Co.,ltd

Company Background: Changshu Jiarun Weaving Co., Ltd., established over 20 years ago, is a leading manufacturer in China specializing in microfiber production. The company offers a diverse range of products, including microfiber cleaning cloths, fabrics, kitchen towels, car washing/drying towels, and microfiber mops.

Key Products and Services: microfiber fabrics, kitchen towels, car washing/drying towels, microfiber mops.

Headquarters: Changshu City, Jiangsu Province, China.

Key Markets: Domestic and international markets.

Add: No. 68, Silver Ring Road, southeastern Development Zone, Changshu City

Website: https://www.js-jiarun.com/

2. Wuxi Xinya Micro Fibrous Co., Ltd.

Company Background:Leading microfiber cloth manufacturers and suppliers in China for the Microfiber products like microfiber cloth, microfiber pouch, focus on the eyewear industry,offering custom microfiber cloths made in China at competitive prices.Key Products and Services: Microfiber cloth for eyeglasses, screen cleaning microfiber cloth,

Headquarters:Wuxi, Jiangsu

Key Products: lens cloth,microfiber pouch and cleaning cloth

Certifications: ISO 9001, OEKO-TEX, BSCI

Key Markets: USA, Australia, Japan, Canada, and more than 30 countries worldwide

Add: D08 Liandong Yougu, Zhangjing, Xibei Town, Xishan District, Wuxi City, Jiangsu, China.

Website:https://www.wxxymicrofibercloth.com

3. Wuxi East-Sunshine Textile Science and Technology Co., Ltd

Company Background:Established in 2005, is a leading microfiber cloth manufacturer in China. The company specializes in the production of microfiber cleaning cloths, pouches, gloves, and other related products.Key Products and Services: Microfiber cleaning cloths, pouches, gloves.

Headquarters: Wuxi, Jiangsu

Key Products: Microfiber cleaning cloth, eyeglasses cloth, jewelry cleaning cloth, jewelry pouch, microfiber pouch

Certifications: ISO 9001, BSCI

Key Markets: Domestic and international markets.

Add: Huaqing Chuangzhi Park 5-702, Economic Development Zone, Wuxi, Jiangsu, China

Website: https://www.eastshinewx.com/

-

4. Shijiazhuang Aose Imp and exp Co.,ltd

Company Background:AOSE is a leading Chinese microfiber cloth manufacturer with over 20 years of experience. They specialize in producing and distributing premium high-quality microfiber cleaning cloths for various applications.Key Products and Services:

Microfiber bath towels, hair towels, beach towels, dog towels, drying towels for cars, car cleaning brushes, car wash mitts.Headquarters: Wuxi, Jiangsu

Key Markets: America, Canada, Europe, Japan, Southeast Asia.

Address: No. 1, Ruichun Street, Gaoyang County, Hebei Province, China

Website: https://aosehometex.com/

5. Changshu Defu Knitting Co., Ltd.

Company Background:Established in 2006, Changshu Defu Knitting Co., Ltd. is a specialized manufacturer and trader focusing on the research, development, and production of microfiber products. Located in Changshu City, Jiangsu Province, China, the company benefits from convenient transportation access, being approximately 80 kilometers from Shanghai. Defu Knitting is dedicated to producing high-quality microfiber cleaning products for various applications, including household cleaning, car care, and personal use.Key Products and Services:

- Microfiber Towels Designed for car washing, household cleaning, and personal care, offering high absorbency and softness.

Headquarters: Changshu City, Jiangsu Province, China

Key Markets: North America, South America, Eastern Europe, and other international regions.Certifications: ISO 9001:2015 Quality Management System

Add: Building 3, No. 2, Chencun Road, Southeast Street, Changshu, Suzhou, Jiangsu, China 215500

Website: www.defumicrofiber.com -

6. Hebei Jiuyuan Textile Group Ltd.

Company Background:Established in 1998, Hebei Jiuyuan Textile Group Ltd. is one of the earliest microfiber manufacturers in China. The company operates a comprehensive production process, including spinning, knitting, dyeing, cutting, sewing, packaging, and inspecting, with a daily output of 200,000 pieces.Key Products and Services: Cleaning products, bath products, sports products

Headquarters: Weixian, Xingtai, Hebei Province, China.

Key Markets: Europe, the USA, Japan, South Korea, South America, the Middle East, Southeast Asia.Add: No.2 North Ring Road Economic Development Zone Wei County, Xingtai, Hebei, China. 051130

Website: https://www.chinajiuyuan.com/

7. Yuanshi County Zhengheng Textile Co., Ltd

Company Background:Founded in 2008, Yuanshi County Zhengheng Textile Co., Ltd. specializes in producing a wide range of microfiber products, including hair-drying towels, hand towels, bath towels, bathrobes, tea towels, cleaning towels, and car cleaning towels. The company emphasizes innovation and strict quality inspection to ensure high-quality products.

- Key Products and Services: Hair-drying towels, hand towels, bath towels, bathrobes, tea towels, cleaning towels, car cleaning towels.

- Founded: 2008.

- Headquarters: Yuanshi County, Shijiazhuang City, Hebei Province, China.

- Key Markets: International markets.

- Add: Zhengheng Textile Factory,Yuanshi South Industry Zone, Yuanshi Town,Shijiazhuang City,Hebei Prodince,China.

- Website: https://zhenghengtextile.com/

8. Changshu Gongsheng Textile Co., Ltd

- Company Background:Established in 2017, Changshu Gongsheng Textile Co., Ltd. is a manufacturer specializing in microfiber fabrics. The company supports both domestic and international processing enterprises with a variety of microfiber fabrics to meet diverse market needs. Their products are primarily used for making microfiber dish cloths, towels, mop cloths, and other cleaning wipes. The factory operates one production line for adding and twisting yarn, along with 14 weaving machines, including four high-speed machines imported from Germany, achieving a daily weaving capacity of approximately 30 tons of fabric.

- Key Products and Services: Microfiber dyed fabric, microfiber greige fabric, microfiber yarns and threads.

- Founded: 2017.

- Headquarters: Changshu City, Jiangsu Province, China.

- Key Markets: Domestic and international markets, including Russia, Mexico, and Egypt.

- Contact: No.35 Nanyuan Rd, Tonggang Industrial Park, Meili Town,Shangshu City, Jiangsu Province, China

- Website: https://fabricmicrofiber.com/

9.Changshu Jieyu Textile Co., Ltd.

- Company Background:Changshu Jieyu Textile Co., Ltd. is a professional manufacturer of microfiber cleaning products, located in Changshu City, Jiangsu Province, near Shanghai port. With decades of experience, Jieyu Textile offers a wide range of microfiber products for various applications, including household, automotive, pet care, and sports. The company emphasizes strict quality control procedures and comprehensive order follow-up processes, earning a good reputation among buyers worldwide.

- Key Products and Services: Microfiber cleaning cloths, towels, mops, and related cleaning products.

- Founded: Over 20 years ago.

- Headquarters: Changshu City, Jiangsu Province, China.

- Key Markets: Global markets, serving buyers across the world.

- Contact: No.7 Kangbo Avenue, Baimao, Changshu City, Jiangsu Province, China

- Website: https://cnecotex.com/

10.Changshu Power Clean Co., Ltd.

- Company Background: Changshu Power Clean Co., Ltd. is a manufacturer of innovative, solution-based microfiber cloth products for both the commercial and household cleaning markets. The company operates a production area of over 12,000 square meters with more than 150 employees. They possess a complete line of production facilities and equipment, including weaving, cutting, sewing, plastic injection, and automatic overlocking machines. The company has passed the factory inspection of Bureau Veritas International.

- Key Products and Services: Microfiber cloths, towels, mitts, sponges, mops, and dusters.

- Founded: Over 15 years ago.

- Headquarters: Changshu City, Jiangsu Province, China.

- Key Markets: United States, Australia, Japan, Germany, and nearly 69 countries and regions worldwide.

- Contact: Building C, Area A, Intelligent Manufacturing Industrial Park, No. 58, Muchang Rd, Haiyu town, Changshu

- Website: https://www.cnpowerclean.com/

Microfiber cloth Industry Trends

The microfiber cloth industry is experiencing several notable trends:

1. Market Growth

- Significant Expansion: The global microfiber cleaning cloth market is projected to grow from USD 2,450 million in 2023 to USD 32,000 million by 2032, with a compound annual growth rate (CAGR) of 24% during 2024–2032.

2. Diverse Applications

- Broadening Use Cases: Microfiber cloths are increasingly utilized across various sectors, including household cleaning, automotive care, industrial applications, and personal care products

3. Environmental Considerations

- Eco-Friendly Demand: There is a growing consumer preference for sustainable and environmentally friendly cleaning products, leading manufacturers to focus on eco-conscious microfiber options.

4. Technological Advancements

- Innovative Developments: Manufacturers are investing in research and development to enhance microfiber properties, such as increasing absorbency, durability, and antibacterial features, to meet diverse consumer needs.

5. Regional Market Dynamics

- Asia-Pacific Dominance: The Asia-Pacific region, particularly countries like China and South Korea, continues to be a significant producer and consumer of microfiber products, driven by robust manufacturing capabilities and increasing domestic demand.

These trends indicate a dynamic and evolving microfiber cloth industry, with growth fueled by expanding applications, environmental awareness, technological innovations, and regional market developments.

How to Choose the Right Microfiber cloth Factory

When selecting a supplier for microfiber cloths or towels, it’s beneficial to consider the regional specializations within China:

Wuxi, Jiangsu: For soft and thin microfiber cloths ideal for cleaning eyewear, lenses, jewelry, watches, screens, instruments, and appliances, partnering with factories in Wuxi is advantageous. This region is known for its integrated production facilities, encompassing both raw material sourcing and manufacturing processes.

Gaoyang, Hebei, and Changshu, Jiangsu: For regular solid-color microfiber towels suitable for kitchen, household, window, and car cleaning, factories in Gaoyang and Changshu are ideal partners. These areas are home to primary manufacturers with comprehensive textile supply chains, covering weaving, dyeing, and processing.

Guangdong Province: For custom microfiber cloths or towels, suppliers in Guangdong are proficient in providing tailored printing and packaging solutions. They typically source raw materials and excel in customization to meet specific client requirements.

Selecting the right microfiber cloth factory is crucial for ensuring product quality, cost-effectiveness, and timely delivery.

1.Product Range and Customization

Evaluate whether the factory offers a diverse range of microfiber products suitable for your applications, such as cleaning cloths, towels, or specialized items. If you require custom designs, printing, or packaging, ensure the supplier has the capability to meet these specifications.

2. Sample Quality and Prototyping Speed

Request samples to assess the quality of materials, workmanship, and overall product performance. Additionally, consider the factory’s efficiency in producing prototypes, as this reflects their responsiveness and ability to meet deadlines.

3. Pricing and Cost Efficiency

Compare pricing among different suppliers to ensure competitive rates without compromising on quality. Factories located in regions like Gaoyang, Hebei, and Changshu, Jiangsu, often benefit from integrated supply chains, potentially offering cost advantages.

4. Service and Communication

Assess the supplier’s communication skills, responsiveness, and willingness to collaborate. Effective communication is crucial for addressing concerns, managing orders, and ensuring a smooth partnership.

- 5. Certifications: Some brands ask specific certificate for factory like BSCI, Sedex, or GRS.

Easypromogift makes custom Microfiber cloth easy for you

Easypromogift leverages China’s comprehensive supply chain advantages, maintaining long-term relationships with stable raw material suppliers and collaborating with multiple primary factories. This enables us to coordinate production capacity and delivery schedules effectively. By focusing on custom microfiber cloths, we can meet a wide range of client requirements.

Diverse range of textile products, including eyeglass cloths, pouches, cooling towels, sports towels, beach towels, bath towels, hair drying caps, car cleaning cloths, and more.

-

- By choosing Easypromogift for your custom microfiber cloth needs, you benefit from a partner dedicated to enhancing your brand’s visibility through high-quality, customizable promotional products.

ConclusionThis article provides a comprehensive overview of the microfiber cloth industry, including manufacturing processes, supply chain centers, product offerings, essential certifications, leading manufacturers, current industry trends, and guidelines for selecting the right factory.

Understanding the microfiber cloth industry is essential for making informed decisions, whether you’re a business or a consumer. By familiarizing yourself with manufacturing methods, key supply chain locations, product varieties, and necessary certifications, you can better navigate the market. Staying updated on industry trends and carefully choosing manufacturing partners ensures that you align with quality standards and meet market demands effectively.

-

- Microfiber Cleaning Cloths: Ideal for general cleaning tasks, these cloths effectively remove dust, dirt, and moisture from surfaces without the need for chemical cleaners.Phone /Laptop/computer Screen cleaning, eyeglass lens cleaning cloth, jewerly cleaning and polish, instrument cleaning etc